3D Printing

Dutton Engineering Metal Fabrication Service

3D Printing

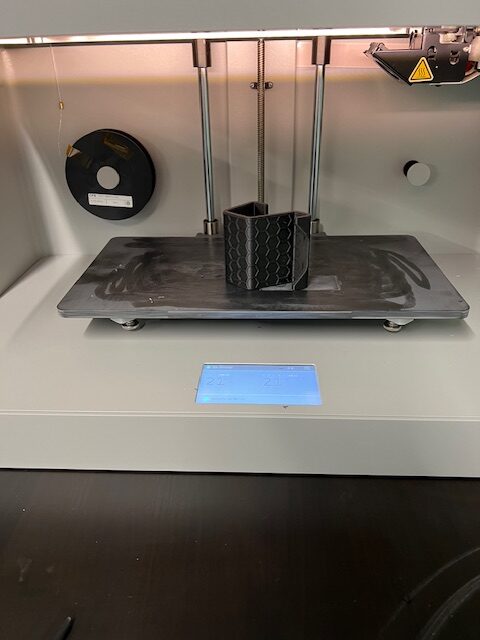

Markforged Mark Two 3D Printer

At Dutton Engineering, we’re proud to announce the addition of cutting-edge technology to our capabilities: the Markforged Mark Two 3D Printer. This state-of-the-art machine enhances our ability to deliver innovative, high-performance solutions with unprecedented precision and speed.

What It Means for You:

Our new 3D printer allows us to create high-strength, lightweight components using advanced composite materials, including Onyx (carbon fiber-filled nylon) and reinforced options like HSHT Fiberglass. This enables us to produce parts with:

Aluminum-like strength

Exceptional durability

High thermal and chemical resistance

Applications:

The Markforged Mark Two expands our ability to serve industries requiring custom solutions, including:

Prototyping: Rapid creation of high-fidelity prototypes.

Tooling and Fixtures: Durable jigs, fixtures, and custom tooling to streamline production.

End-Use Parts: Lightweight, high-strength components for specialized applications.

Advantages of 3D Printing

Precision Engineering:

With a build volume of 320 x 132 x 154 mm and advanced software integration, we can manufacture parts with:

Unparalleled accuracy

Seamless surface finishes

Tailored reinforcements for optimal performance

Sustainable Solutions:

Our adoption of 3D printing aligns with our commitment to sustainability. By minimizing waste and utilizing efficient production methods, we reduce our environmental impact while maintaining our high standards of quality.

Explore the Possibilities Discover how our Markforged Mark Two 3D Printer can revolutionize your projects. Contact us today to learn more about how this new technology can deliver the solutions you need, faster and better than ever before.